Week 8 SDX placement

20th mar- I’ve updated the business card, here it is below. Sent off for printing.

The colours when printed might not be as bright as these, looking for a more muted colour pallet but we will just have to wait and see once they are printed off. Also the bio got a wee update, just some grammar errors, needs a little more refinement and maybe a final shot of the finished product once the feedback comes through.

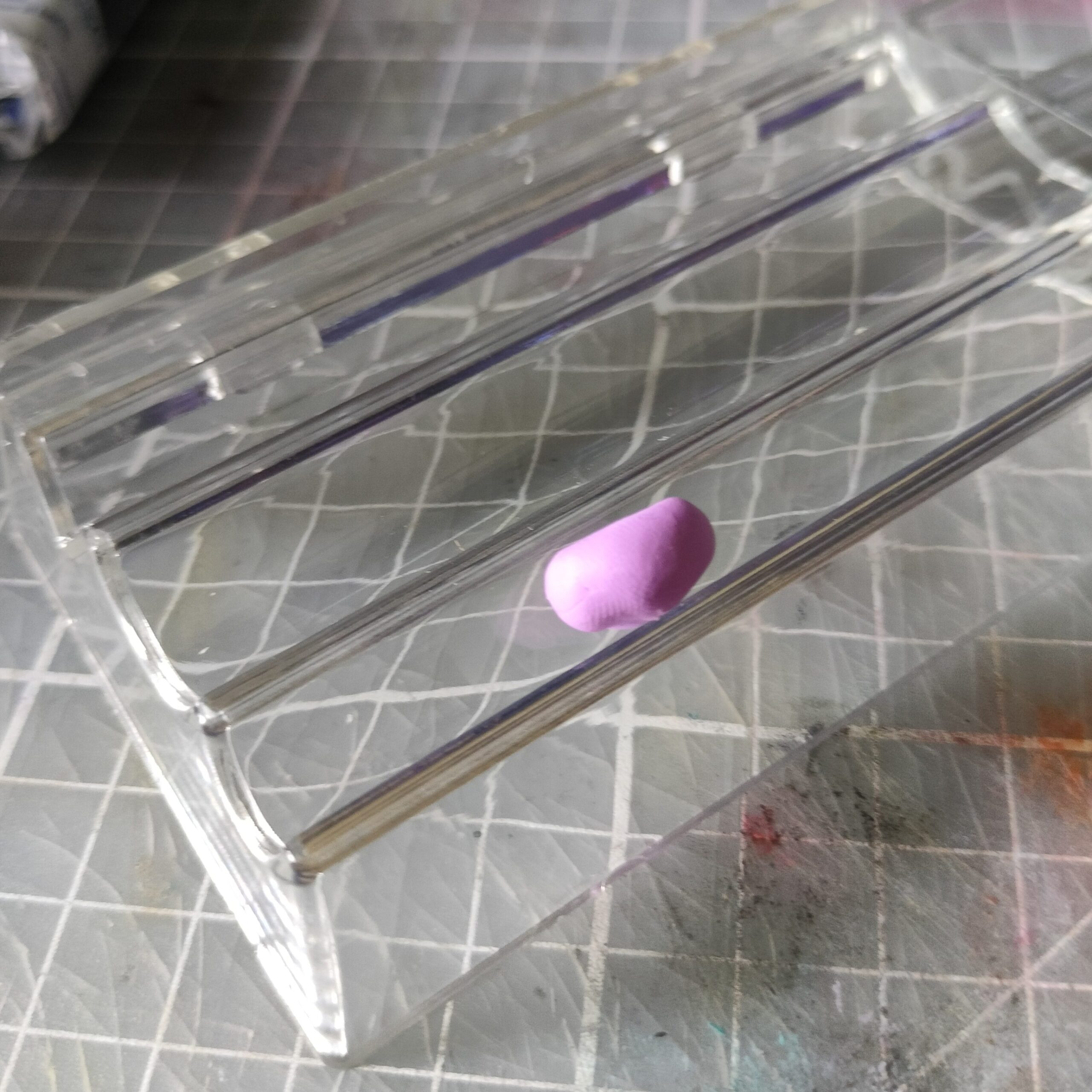

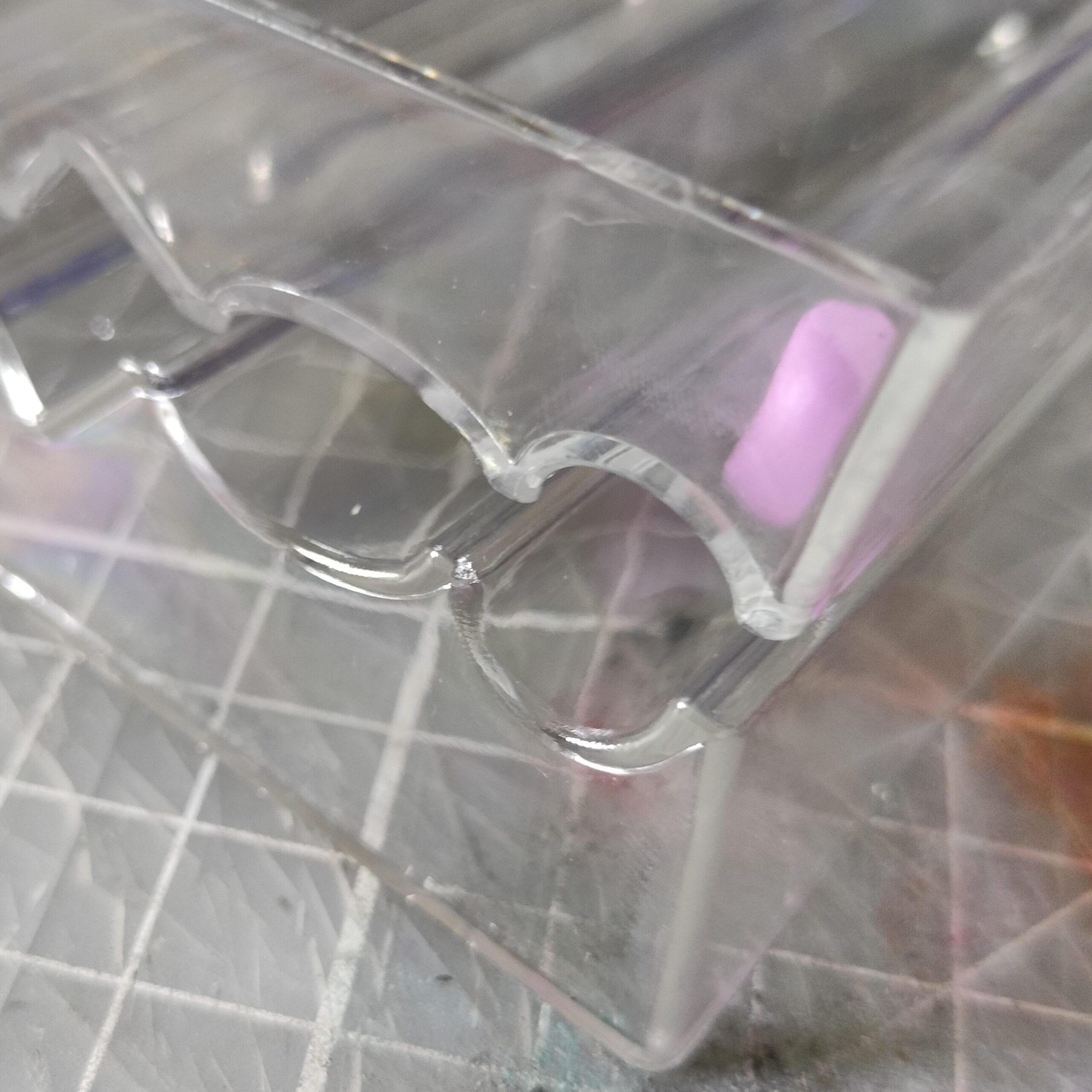

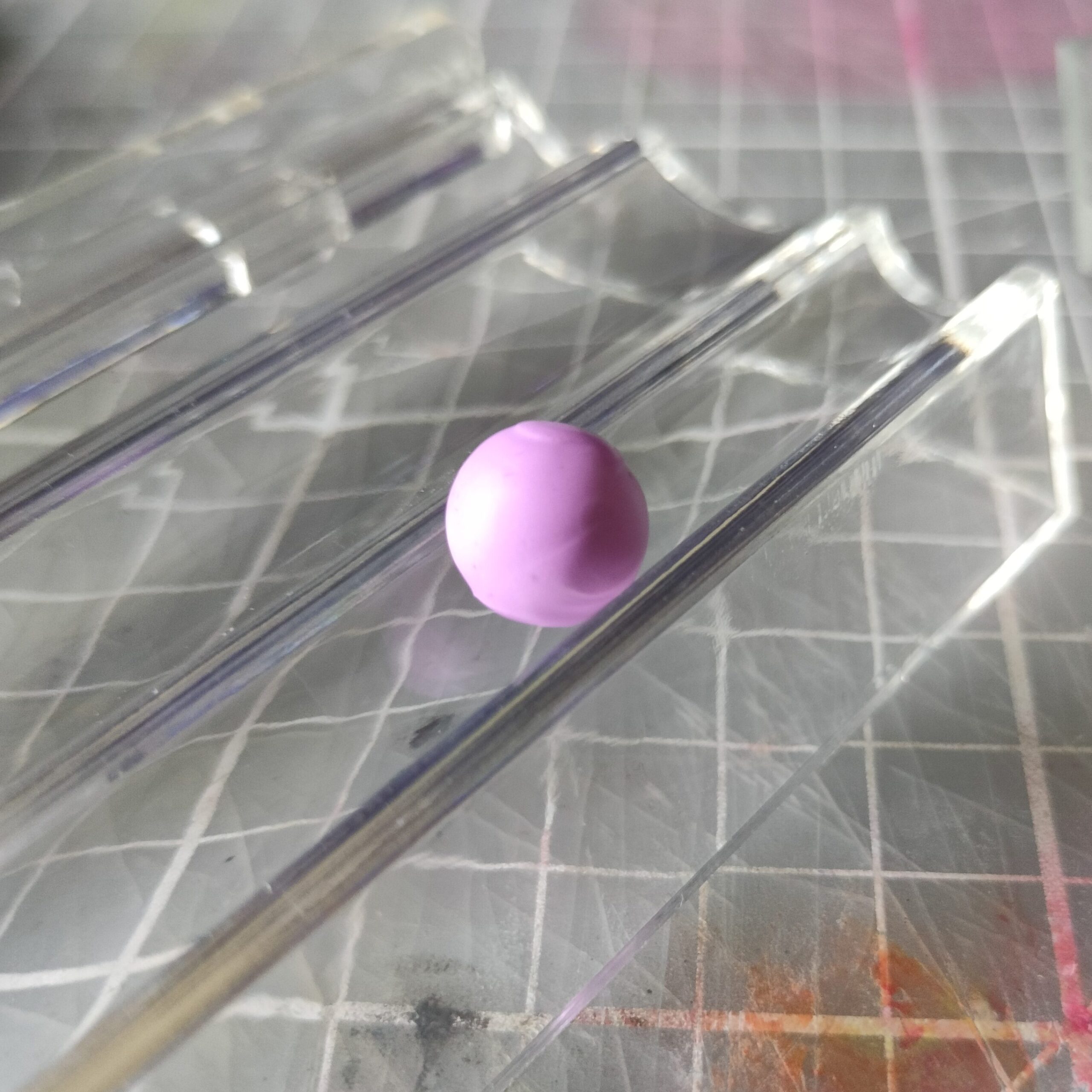

Now just playing around with some new tools I got, helping to get more consistency throughout the products.

Near perfect ball, with this tool being able to make a total of 3 different types of beads, just need to be careful with the clay when trying to put a hole into it.

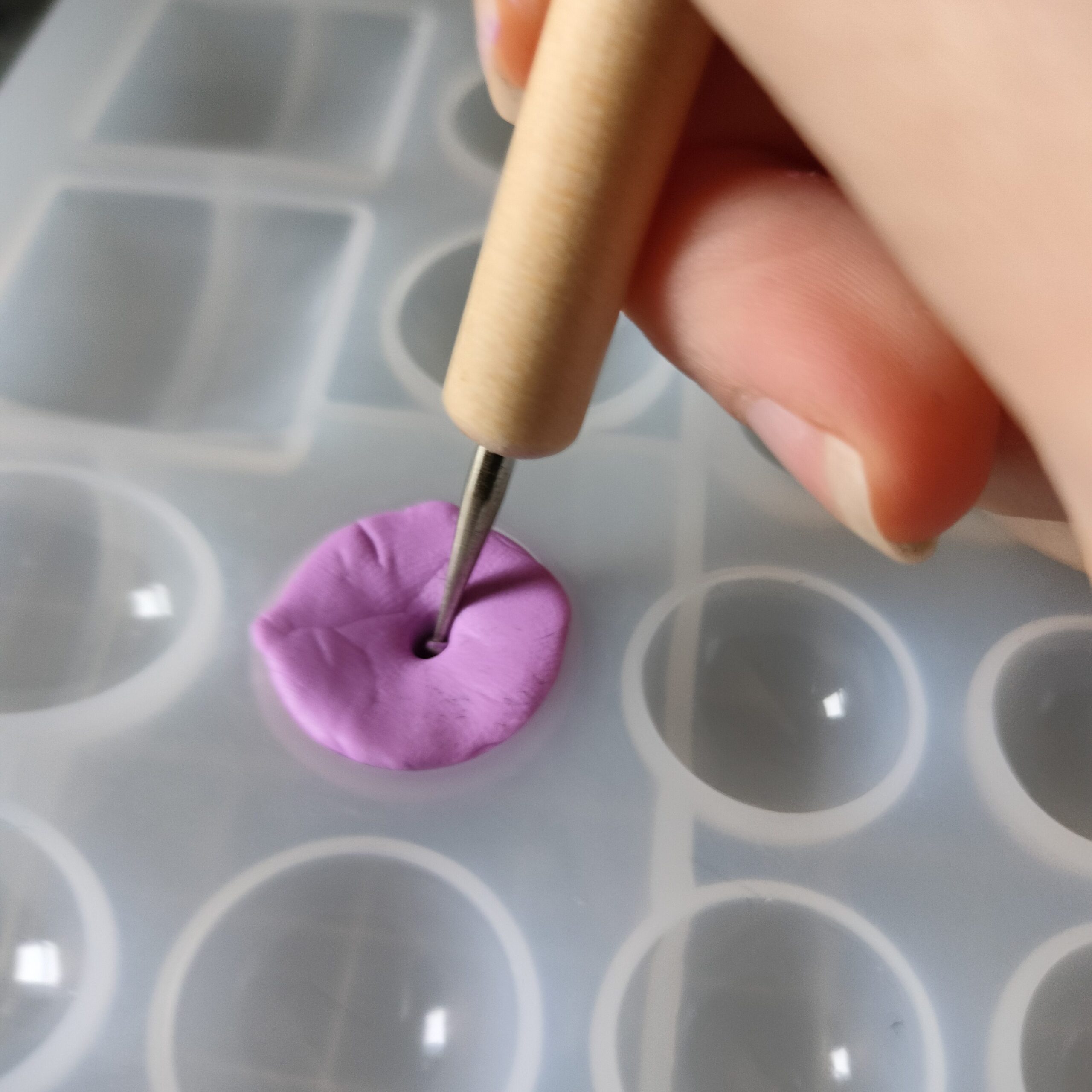

The next tool to test was this silicon mould, it should help to get cleaner half spheres.

This tool also helped to just get a smoother finish, just need to be careful to not get dust and stuff on the beads. Clean the tools between uses. The clay is very soft so also need to be careful when de-moulding the parts. But I think this will be the best way to get better consistency.

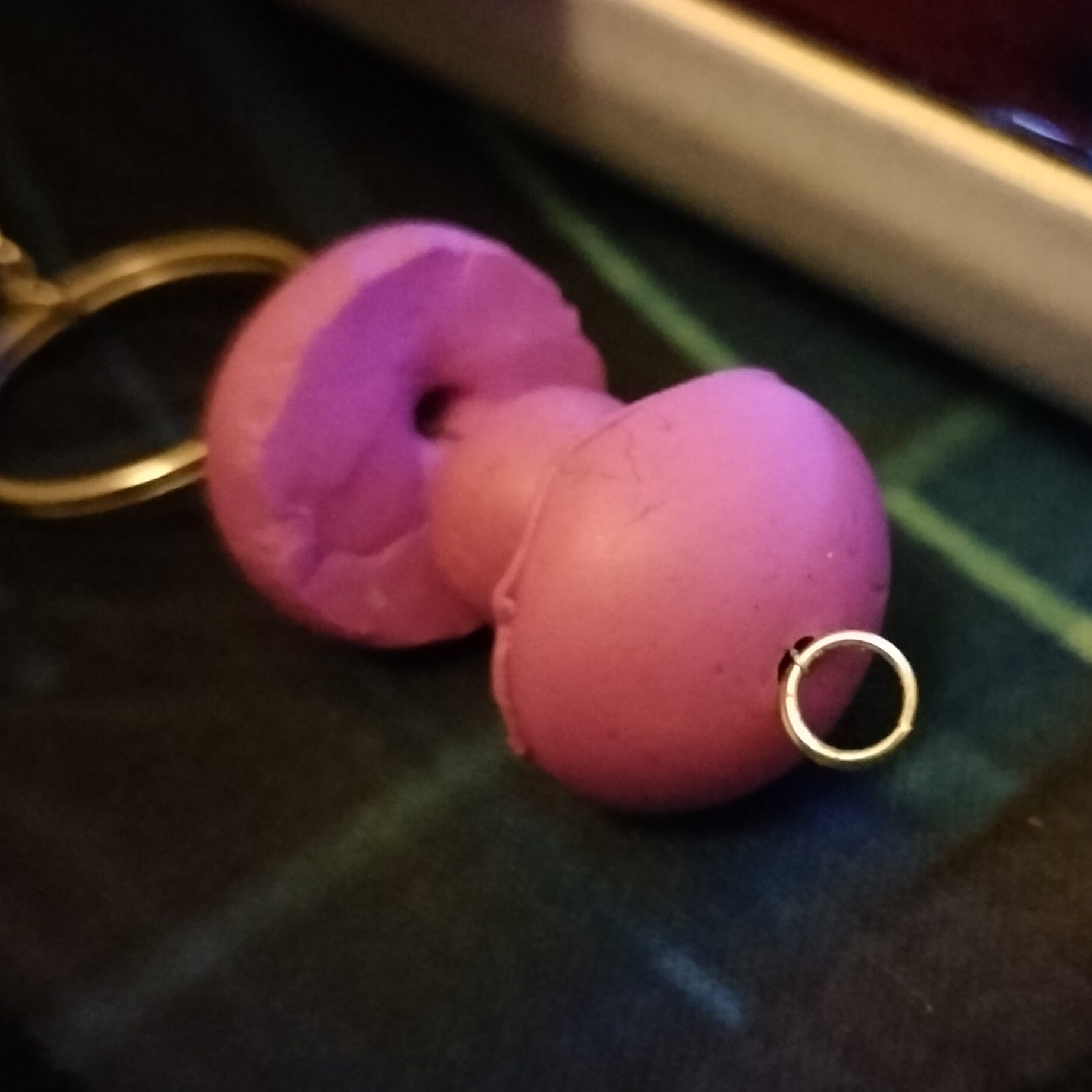

22nd mar- I baked the clay made using the new tools, and made a tester piece. Wearing it for a day and storing it in my bad for a day to see what wear and tear might show up as to make the product as solid as possible. found out that the way i had done the wiring for the product would unfurl at the top and bottom, which was a big problem as the beads could fall off.

To fix this I put a ring of metal at the top and bottom, then gently twisted the wire around itself so that it was fixed in place then snipped it off and tucked in the wire end so it cant stab anyone.

These metal loops also help for putting it onto and off the necklace, making it safer and easier to move it onto a keychain, to suit the users needs.

Thinking about how to package this up, the keychain isn’t the main draw so I feel I should maybe store this at the back or consider selling both keychains and necklaces. If it is sold as one item it might be worth putting instructions on how to assemble and de-assemble this product into its different uses.

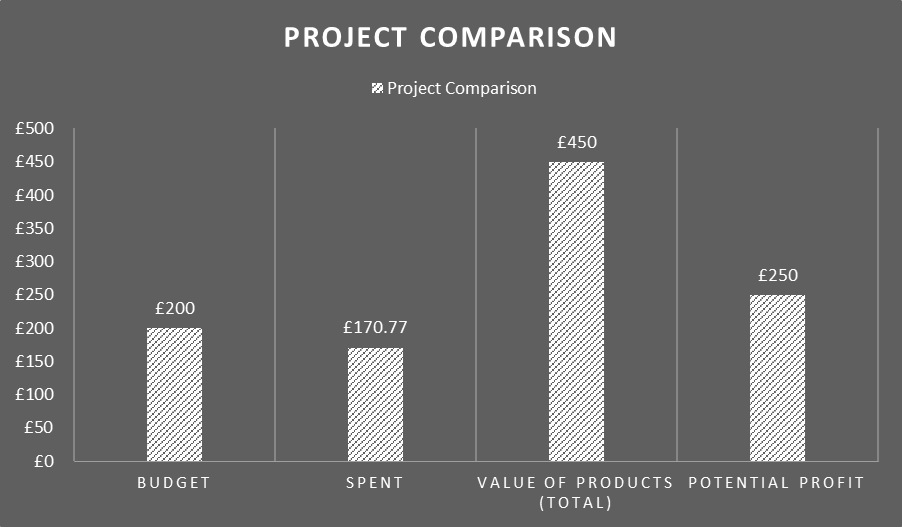

This chart shows the projections for selling the necklaces at £15 a necklace. This means it costs £5.69* to make each product (*approximately). With a total profit on each necklace being Approximately £8.33, which is more than double the cost it took to make the product. These spending costs include tools, materials, display items, and business cards. If this business was to continue it wouldn’t suffer the same start up costs for tools and display items. With a less frequent top up for business cards, and a more frequent top up for materials. With the business cards only costing £0.35 per card. Materials would vary more as times change and things like metal become more expensive, but not a massive cost this business couldn’t handle, with room to expand if this product sells in steady volumes.